Ingredients for products of the EKO brand are being grown on the fields of Krasnodar region. Today it is one of the leading Russian regions by production and processing of agricultural products and supply of food to industrial centres of the country.

Cannery industry predominates over the other sectors of food production in Krasnodar region. Agricultural land of Krasnodar region constitute one-tenth part of all lands of the Southern Federal Area. Chernozem soils predominate on the plains of the region, and they occupy 4805 thousand hectares (it is more than 4% of Russian entire quantity and about 2% of world entire quantity of such soils). Chernozem soils are dark-coloured, they are unconsolidated and well-structured. Besides they are rich in nutrients and produce high yields of agricultural products.

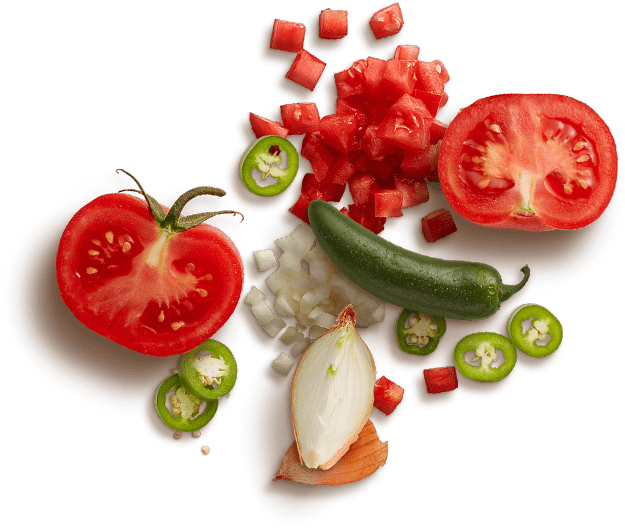

Thanks to natural environment of Krasnodar region it is possible to grow there all the agricultural products of the temperate zone and even some subtropical plants.

Quality control of soils and agricultural products is provided by the system of Consolidated centre of satellite-based monitoring of Krasnodar region. This centre was the first to be opened in the country in 2013 as a part of development of precision farming conception.

It allows to monitor every field that is situated on the territory of the region and to control:

The use of such system was possible since Krasnodar region had been the first to make complex digital passportisation of fields.

Our cannery producing plant is located in Krasnodar region that is one of the most prospective regions from the point of view of micro- and macroeconomic indicators, investment appeal, climate and quality control of soils.

The main advantages of our plant are its enormous production capacities and use of modern equipment that provides high quality of final products. The plant of our company is one of the largest processing enterprises on Kuban. It is the leader of cannery industry in the region by production of canned fruit and vegetables and by processing of vegetables.

Production capacities of our plant are about 130 million of cans of preserves per year. The number of processed fresh vegetables is close to 80 thousand tons.

At our plant there is a modern laboratory where fresh vegetables and final products are tested in several stages such as measuring the level of nitrates, studying organoleptic qualities, doing physicochemical and microbiological analysis.

Our production lines are fully automated from providing empty cans upto packing the final products. So influence of the human factor is minimal.